Warning

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

When routing cables, AS/NZS 3000 requires that they be protected from mechanical damage. This includes protection from cut edges of the frame and any fasteners installed by following trades. The drawing of cables through service holes that are not protected should be avoided.

Routing cables through LGS frames may result in cable being placed within the cavity of the section. These cavities are areas that may receive self-drilling fasters and/or nails during and after construction. Examples of this are studs and ceiling battens. While technically acceptable within the requirements of AS/NZS 3000 (Section 3.9.4.4), running cables within channels is not deemed best practice as later trades may drill or screw into these cables. Where this cannot be avoided, the requirements of AS/NZS 3000 must be adhered to.

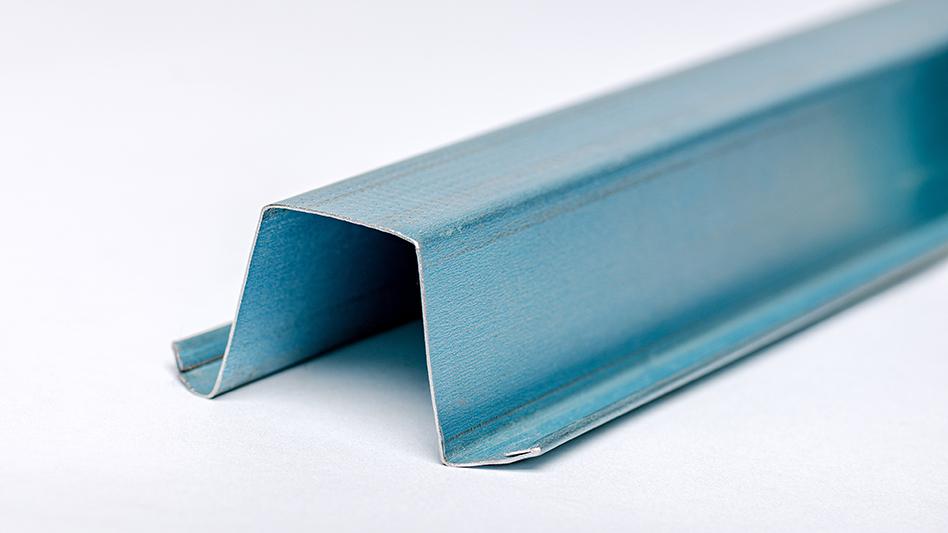

The photo below shows a ceiling batten, where the section is open from the top. The second photo shows a wall stud where plasterboard would later be attached to the flanges. In both situations, AS/NZS 3000 allows cables to be run through these channels. However, this is not considered best practice, as these sections receive fasteners when internal linings are attached.

This guide contains information to help you meet your obligation to comply with AS/NZS 3000 when working on steel framing buildings

This guide explains detailing process where electrical detailing is entered prior to the frames being fabricated.

In this topic, we look at cable installation in LGS frames.