Warning

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

Light Gauge Steel (LGS) is a popular alternative to standard construction materials.

Look at the design process through to manufacturing and assembling LGS frame components in the factory.

In this topic we look at the specific safety considerations when working with LGS framing and components.

In this topic, we look at a few common tools that make LGS installations both safer and more efficient.

While many on-site activities are the same regardless of construction materials, working with LGS has some specific differences.

Learn about fasteners for frame installation and tie down bolts to connect walls to concrete floors.

This topic shares tips for the handling and storage of LGS frames when on site.

Learn how to fasten LGS wall frames to the flooring system and join wall frames together.

Learn about the orientation and layout of floor trusses & see examples of different systems.

This topic explores the differences in various truss systems and key installation differences. It also covers fixing LGS framing members to structural steel.

Find out how to remove the door bottom plate in a few easy steps.

Regardless of system or technology, LGS wall frames require bracing to resist the horizontal shear forces generated by wind.

Damp-proof courses (DPCs) provide important protection against corrosion of LGS framing and are recommended as best practice. Find out more!

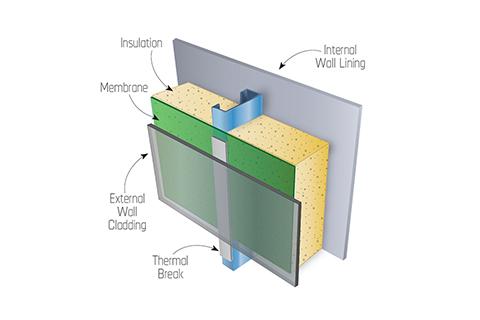

This topic outlines when thermal breaks are required and methods to achieve compliance.

There may be instances when you need to make modifications on-site when working with Light Gauge Steel.

This topic covers the steps needed to replace a frame component that has been damaged.

This topic outlines how to modify a window opening, or move a door, efficiently on-site.

Noggins can be made onsite from LGS or timber, or proprietary products can be used. Find out more in this topic!

At times it might be necessary to repair a screw that has been stripped or overdriven. Its easy to do in 3 steps!

This topic looks at methods to create new service holes and recommended hole sizes and layouts.

Compliance is essential for all construction activities and Light Gauge Steel (LGS) is no exception.

This topic discusses galvanic corrosion and outlines materials that can be used and those that must be isolated from LGS.

This topic looks at Deemed-to-Satisfy solutions for construction in designated bushfire prone areas.

In marine zones, a greater level of isolation from the external environment is required to prevent salt-laden air from contacting the LGS frame.

Learn more about working with LGS. Explore our how-to videos and other resources.