Warning

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

Please be advised this website is for internal review purposes only and is not to be distributed until advised.

LGS sections are cold-formed from thin steel gauges and can vary from 0.42mm to 3.2mm in thickness. Sections used for roof trusses, wall frames, floor subsystems and battens typically have a base metal thickness (BMT) of between 0.42 and 1.2mm and weigh less than 2kgs per lineal metre. The popularity of this material is driven by improvements in design and installation systems, making LGS easy, fast and safe to install.

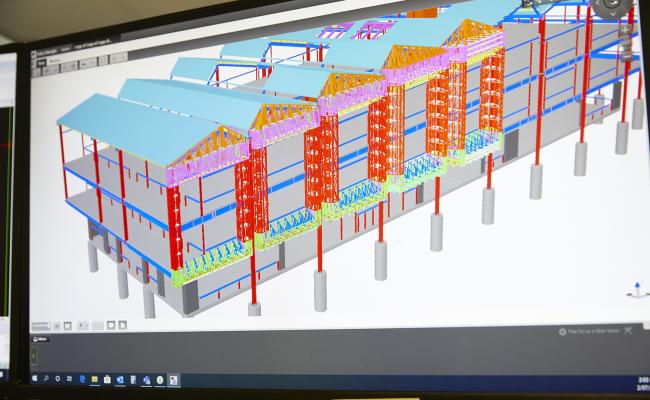

LGS can be used in many applications in low to mid-rise detached or semi-detached residential and commercial buildings. Typically framing applications are up to 3 storeys but LGS also has applications up to 9 floors. LGS also lends itself to prefabricated modular elements such as floor cassettes and bathroom pods as well as façade construction.

On-site labour is a significant cost in construction and prefabricated building systems can minimise labour costs, reduce construction times, assist on-site safety and improve quality and compliance.

These introduction topics feature useful information for those who are either new to working with LGS or would like a quick reminder of key aspects.

Learn about the design process through to manufacturing and assembling LGS frame components in the factory.